Propolis-modified UF adhesives: a bio-based route to high-performance wood composites

Chiara Baldini

NETZSCH ANALYZING & TESTING

The growing demand for sustainable alternatives in the wood panel industry is driving research toward biobased additives that can improve adhesive systems.

Propolis extract – a resinous compound collected by bees from plant sources – is one such natural candidate and has shown promising potential as a functional modifier for urea-formaldehyde (UF) resins, the most widely used adhesives in particleboard manufacturing.

A recent study published in the European Journal of Wood and Wood Products examines the incorporation of propolis into UF adhesive formulations and evaluates its influence on the curing behavior, thermal stability, and mechanical performance of the resulting wood composites.

This research was carried out in collaboration with Poznan University of Life Sciences, Poznan University of Technology, and NETZSCH Instrumenty Poland.

INVESTIGATING CURING KINETICS AND THERMAL BEHAVIOR WITH DSC AND TGA

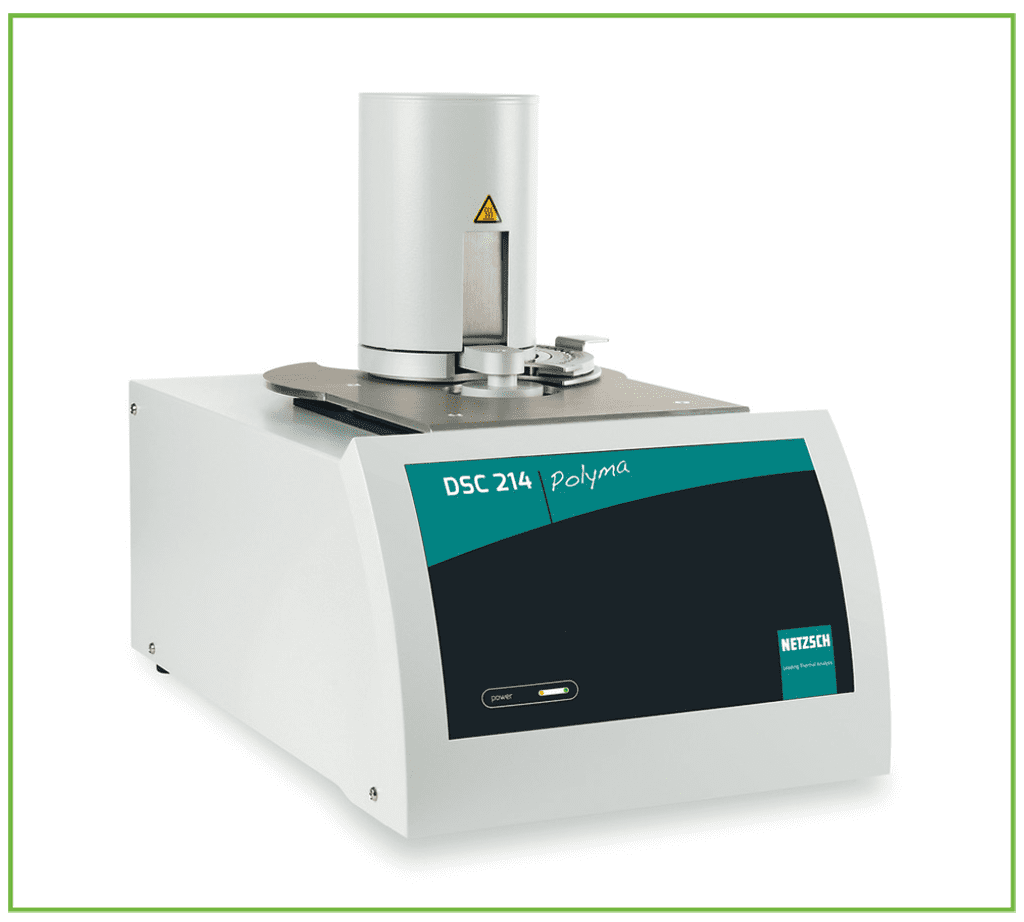

To assess the impact of propolis on the curing kinetics of UF resins, the study employed Differential Scanning Calorimetry (DSC) using a NETZSCH DSC 214 Polyma analysis instrument.

Analyses were conducted in high-pressure crucibles under a nitrogen atmosphere to minimize water loss during heating.

The results indicated an accelerated cross-linking reaction in propolis-modified formulations, suggesting that the natural additive has a catalic effect on resin polymerization.

Further insights into thermal stability were obtained through Thermogravimetric Analysis (TGA), performed with the NETZSCH TG 209 F1 Libra thermobalance.

The data revealed an improved thermal degradation profile of the cured adhesives, confirming propolis’ stabilizing role in the thermoset network.

PERFORMANCE BEYOND THERMAL PROPERTIES

In addition to thermal behavior, the study examined several key performance indicators of the developed particleboards, including mechanical strength, moisture resistance, and formaldehyde emissions.

The modified UF adhesives demonstrated a favorable balance between physical properties and environmental impact, aligning with the industry’s goals of reducing emissions without compromising durability or usability.

These results reinforce the importance of natural resin additives such as propolis in the development of lowemission, sustainable adhesives for wood-based materials.

When formulated correctly, bio-based components can provide functional benefits that complement their ecological appeal.

TOWARD ECO-FRIENDLY WOOD ADHESIVES: THE ROLE OF THERMAL ANALYSIS

This research emphasizes the importance of thermal analysis techniques in the formulation and validation of bio-based adhesive systems.

By combining renewable raw materials with advanced thermal analysis methods such as DSC and TGA, researchers and manufacturers can develop adhesive technologies that support both environmental and industrial performance targets.

REFERENCE TO THE ONLINE AVAILABLE ARTICLE

Kawalerczyk, J., Barczewski, M., Woźniak, M., Kuliński, M., Smogór, H., Dukarska, D. & Mirski, R.

Propolis extract as a bio-based modifier of ureaformaldehyde adhesive in particleboard production.

European Journal of Wood and Wood Products, 83, Article 84 (2025).