Overcoming the bonding challenge of polypropylene in industrial manufacturing

David Tobler

SIKA

As polypropylene becomes increasingly common in commercial vehicle construction—especially in lightweight interior panels—many smaller and mid-sized manufacturers face bonding challenges that large OEMs solve with automated surface treatments. This growing demand has led to the development of a new adhesive system specifically tailored for manual processing, providing a practical alternative for those working without plasma or flame equipment.

Polypropylene (PP) is widely appreciated for its low density, chemical resistance, and mechanical properties—qualities that make it an ideal material in automotive, transport, and appliance manufacturing.

However, these very advantages also pose a unique challenge: polypropylene is notoriously difficult to bond with adhesives due to its low surface energy, typically below 30 dyn/cm. This makes the surface “non-stick” for most conventional adhesives.

WHY POLYPROPYLENE IS DIFFICULT TO BOND

At a molecular level, the lack of polar functional groups and the hydrophobic, non-polar nature of PP’s surface prevent the formation of strong adhesive bonds. As a result, adhesives tend to sit on the surface rather than form lasting chemical or mechanical links. This makes untreated PP a poor candidate for structural bonding applications unless the surface is modified.

PHYSICAL SURFACE TREATMENT: THE STANDARD APPROACH

To enable adhesive bonding, PP surfaces are traditionally modified through physical surface treatments. The most commonly used techniques are:

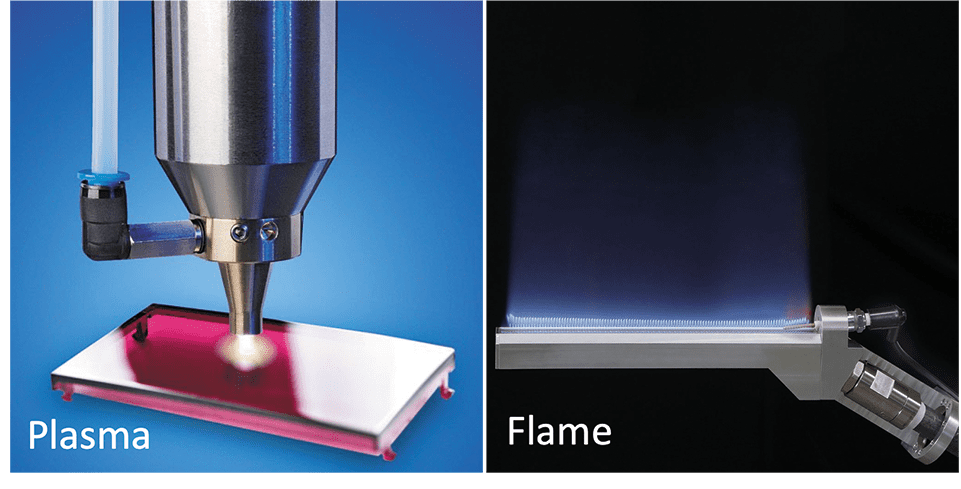

– flame treatment: An oxidizing flame is applied to the surface, increasing surface energy and introducing polar groups. This is widely used in high-through put production.

– Plasma treatment: Plasma ionizes the gas near the surface, creating free radicals that react with the polymer and alter its chemical composition. It offers more control and is effective on complex geometries.

These methods significantly enhance adhesion performance but require capital investment, process control, and in most cases, are limited to automated, high-volume manufacturing environments (e.g., automotive OEMs, appliance manufacturers).

CHALLENGES FOR LOW-VOLUME AND MANUAL MANUFACTURING

Small- to mid-size manufacturers – such as RV builders, last-mile vehicle upfitters, and specialty cargo van producers – often work in lower volumes and rely on manual or semi-automated processes. For them, implementing flame or plasma treatment is frequently not viable due to:

– high equipment cost.

– Need for operator training.

– Process variability in non-controlled environments.

– Safety and environmental concerns.

As a result, these manufacturers face a ‘bottleneck’ when it comes to reliably bonding PP panels without investing in costly pre-treatment infrastructure.

CHEMICAL PRIMING AS A PRACTICAL ALTERNATIVE

For these more flexible production environments, chemical adhesion promoters offer a viable alternative to physical surface activation. In particular, recent developments have focused on solvent-based primers designed for use on glass fiber reinforced PP substrates, which are commonly found in lightweight honeycomb panels used for transport interiors and the construction of cargo vans.

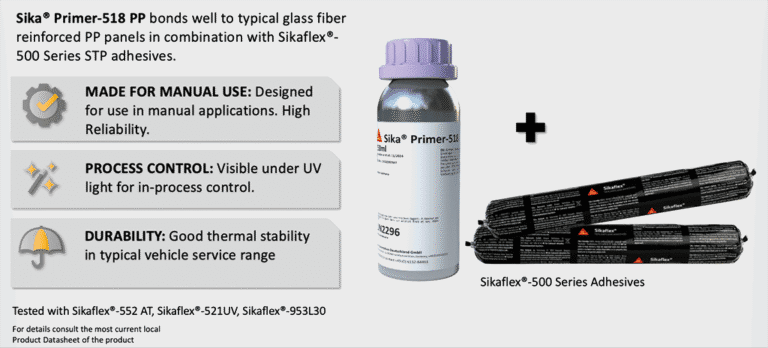

with Sika® Primer-518 PP

One such system combines Sika® Primer-518 PP with Sikaflex®-500 Series, STP (Silane-Terminated Polymer) adhesives.

This combination has demonstrated reliable adhesion on untreated PP-GF panels without the need for flame or plasma treatment. It is designed for manual application, with short flash-off times and the option for process control via UV detection, enabling repeatability in workshop conditions.

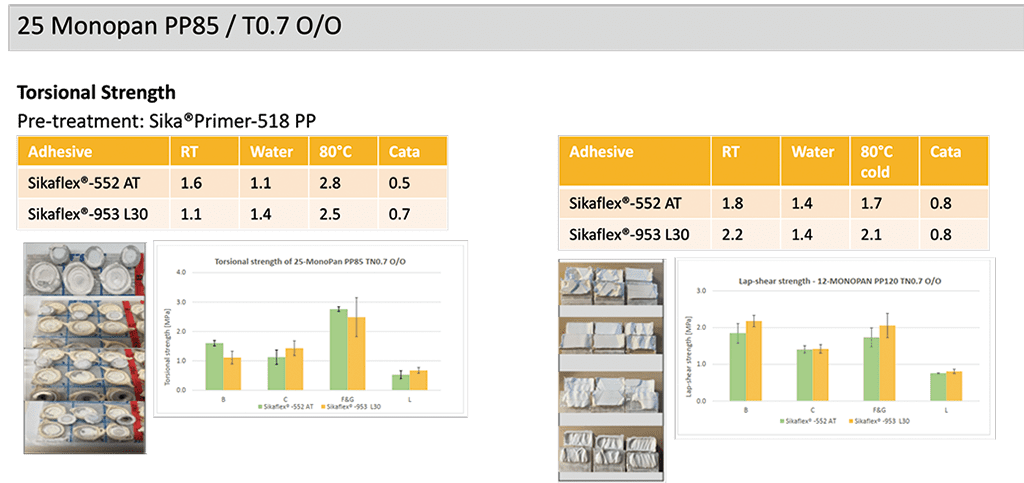

Mechanical testing—such as lap shear and torsional strength—indicates that the bond performance achieved with this primer-adhesive system is sufficient for many noncritical and semi-structural applications in transportation manufacturing.

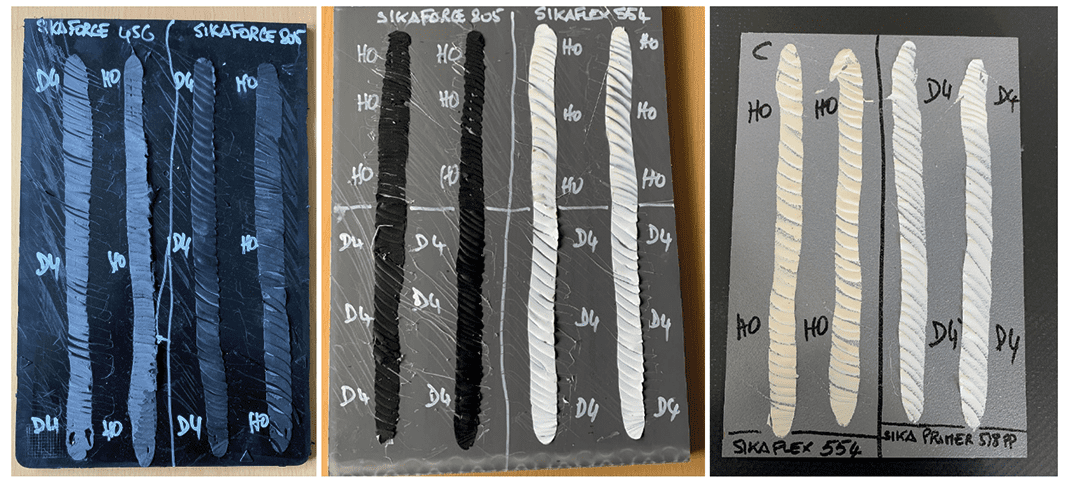

The picture in Figure 4 shows consistently good results of adhesion peel tests on various polypropylene substrates throughout the aging cycle.