Sustainable plywood manufacturing with formaldehyde-free adhesives

Fabio Chiozza, Paolo Lavisci

VINAVIL

INTRODUCTION

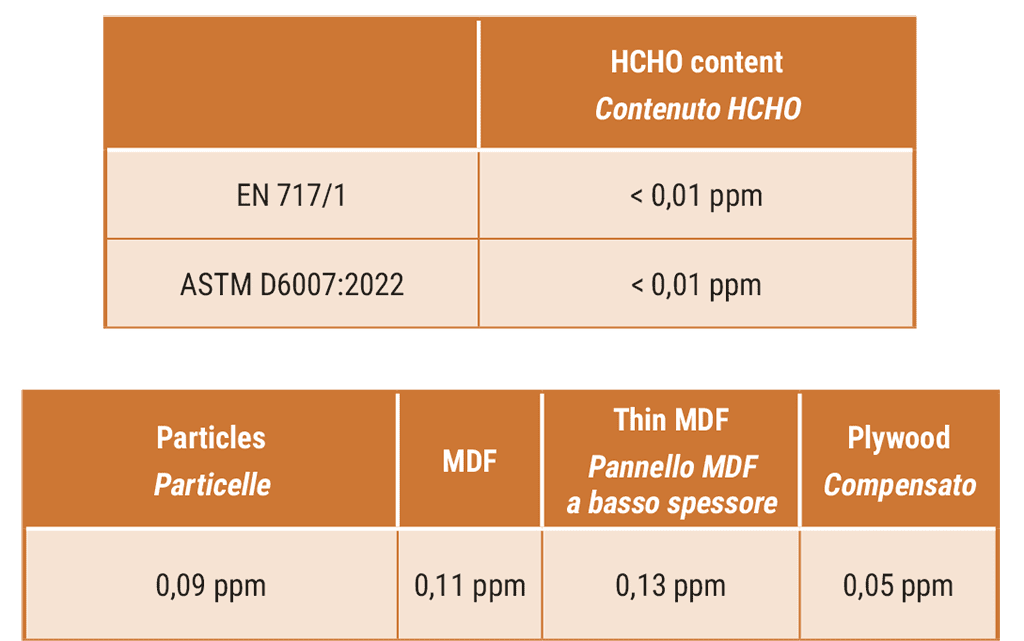

The plywood industry faces increasing pressure to comply with stricter environmental regulations, prioritizing the need for adhesives that do not add formaldehyde and align with both U.S. (CARB, TSCA) and European (REACH, E1/E0) standards for safer, greener manufacturing.

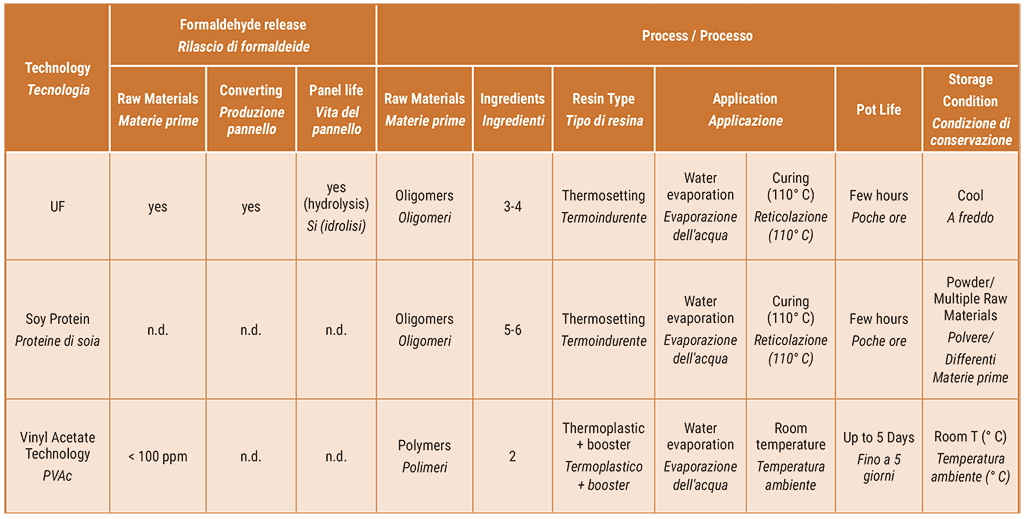

Traditional UF adhesives present challenges such as limited flexibility, susceptibility to hydrolysis, and brittleness over time, compromising product durability. Proteinbased adhesives, though formaldehyde-free, pose challenges with complex curing and limited versatility, often struggling with varying veneer types, thicknesses, and moisture levels. Production efficiency is further hindered by the rigid processing requirements of traditional adhesives. These adhesives typically have a short pot-life, limited storage stability, and generate higher material waste. Moreover, they contribute to elevated rejection rates during production due to inconsistent bonding under varying conditions. This highlights the urgent need for advanced adhesive solutions that improve operational flexibility, reduce waste, and ensure regulatory compliance.

THE SOLUTION IS A PRODUCT STUDIED BY VINAVIL: VINAVIL PW

As formaldehyde emissions face tighter regulations, manufacturers are increasingly turning toNo Added Formaldehyde (NAF) solutions, like Vinavil PW.

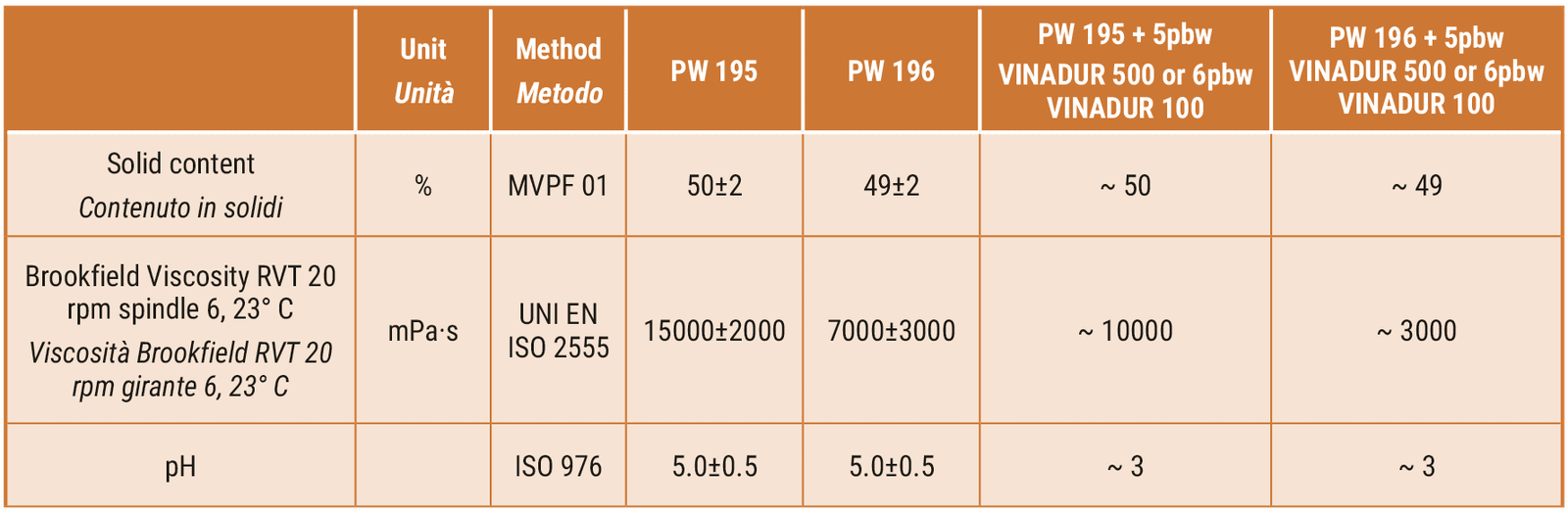

Vinavil PW are nextgeneration formaldehydefree polyvinyl acetate (PVAc) adhesives. The PW range offers superior adhesion, enhanced process efficiency, and long-term stability. PW 195 and PW 196 allow the flexibility to adapt to the range of processing conditions of different plants, with respect to veneer quality and equipment requirements. This ensures low-emission performance, offering a safer, non-toxic alternative to traditional urea formaldehyde (UF) adhesives.

SUPERIOR ADHESION AND VERSATILE APPLICATION

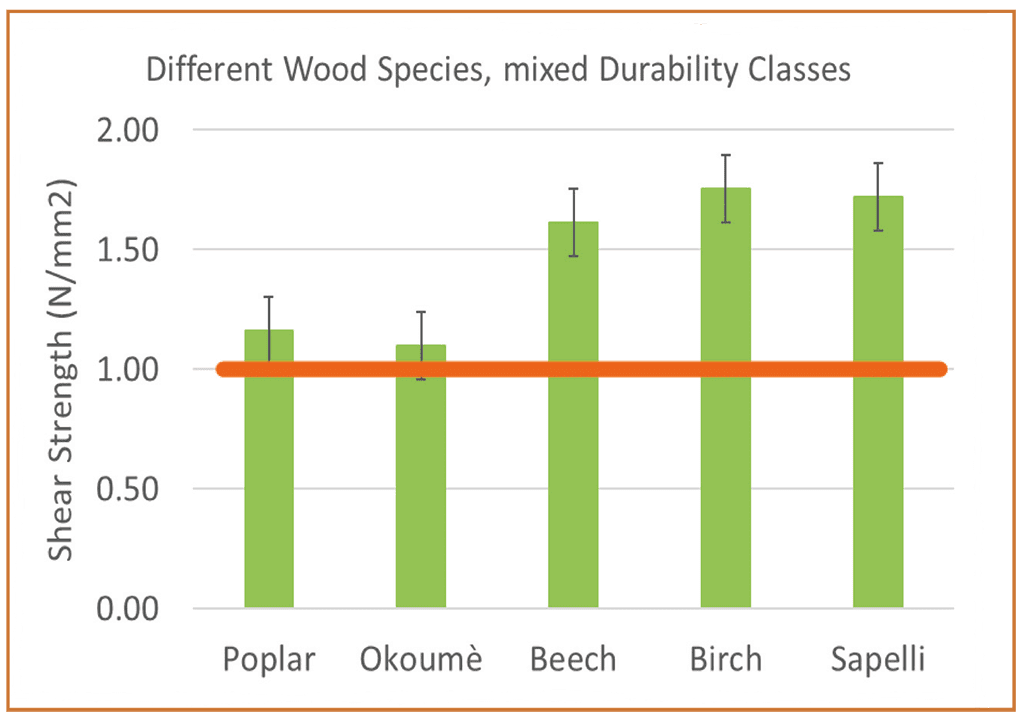

Vinavil PW delivers strong, versatile adhesion across a range of wood species like poplar, birch, beech, eucalyptus, and sapelli, maintaining stability in hot pressing, high-frequency curing, and room temperature pre-pressing methods.

It also performs reliably in high-humidity environments and with varying veneer moisture levels.

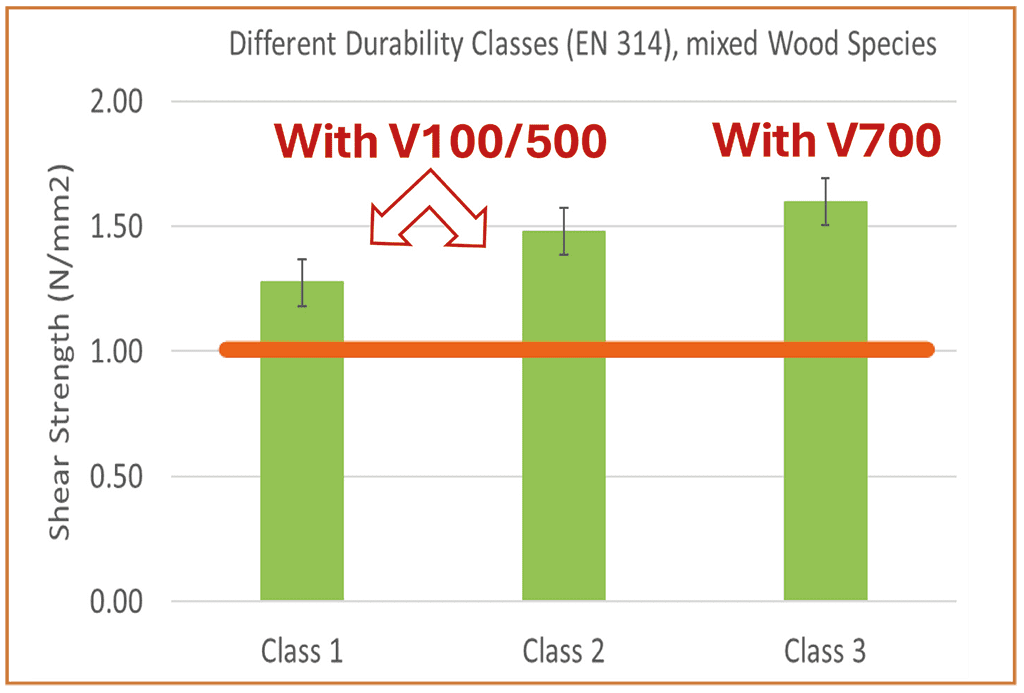

The chart shows the average adhesion performance of Vinavil PW across various wood species, following EN 314 (Plywood – Bonding quality) standards. Data from over 160 tests under different pressing conditions confirm its consistent bonding strength, which is also positively correlated with the veneer’s density and strength. The ‘rolling shear’ test, performed on wet specimens, deems results acceptable when shear strength exceeds 1 N/mmÇ, eliminating the need for further wood failure analysis. Shear strength varies with veneer density, thickness, and peeling quality—denser, thinner veneers typically show higher strength. Vinavil PW reliably meets diverse mill conditions and product performance requirements, offering flexibility across multiple veneer types and surface quality (wettability and roughness). For the same dataset and test methodology described above, this chart illustrates the average performance of Vinavil PW adhesives for the 3 durability classes:

• Class 1: is for interior, dry uses;

• Class 2: for protected external applications and damp internal uses;

• Class 3: for exposure to weather over sustained periods.

Specific adhesives in the Vinavil PW series can be formulated according to the full set of durability, moisture resistance and related performances typically required by plywood panels manufacturers.

PROCESS EFFICIENCY, SUSTAINABILITY AND COST SAVING

Vinavil PW enhances process efficiency and reduces costs with its typically lower glue spread rates, longer pot life and extended open time, minimizing material waste and improving manufacturing flexibility. Its stable formulation reduces defects, delamination, and rejection rates, leading to smoother production and higher output quality.

By eliminating the need for costly ventilation systems— commonly required for formaldehyde-based adhesives— it further reduces operational expenses (Tab. 3).

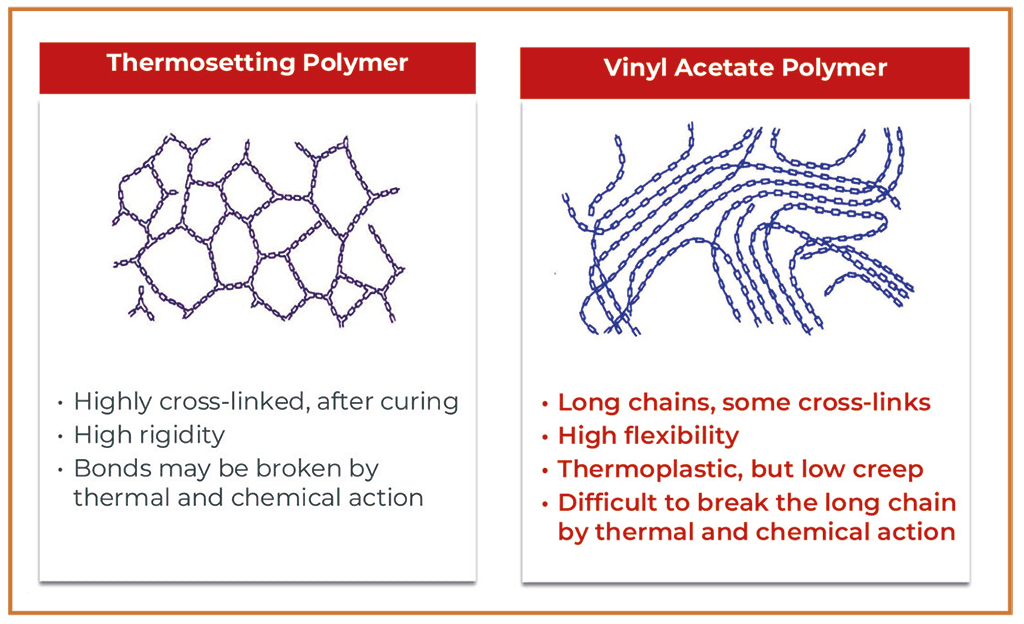

The reasons for this are intrinsic to the physical and chemical nature of pre-polymerized film-forming adhesives, as opposed to the in-situ polymerized thermosetting adhesives, and to the almost century-old expertise developed by Vinavil in formulating them. Designed with sustainability in mind, Vinavil PW supports applications where weight reduction is critical, such as in furniture, packaging, and caravan/motorhome manufacturing. Its lightweight adhesive properties improve material efficiency and product versatility without compromising strength or durability. Additionally, by enabling eco-friendly production practices and reducing material usage, it helps manufacturers align with their sustainability goals while positioning themselves in eco-conscious markets.