The use of Kaneka polymer technology in waterproofing applications

Steven Vandebril

KANEKA BELGIUM NV

Kaneka MS PolymerTM is a well-established technology in construction, primarily used in joint sealants, panel and tile bonding, and flooring adhesives. However, its potential for indoor and outdoor waterproofing applications is less well known.

With excellent adhesion to plastics, polyolefins, concrete, and ceramic tiles, combined with low viscosity and superior watertight properties, the polymer is an ideal material for waterproofing.

It is particularly effective for both new construction and renovation projects.

Additionally, these products are low in VOCs, label-free, and isocyanate-free, making them safe for indoor use. This case study provides an overview of waterproofing applications where Kaneka MS PolymerTM excels.

ROOF WATERPROOFING

Various types of membranes are used on flat and parapet roofs, available as liquid or solid applications.

Kaneka MS PolymerTM serves as a binder for liquid-applied membranes and as an adhesive for solid membranes.

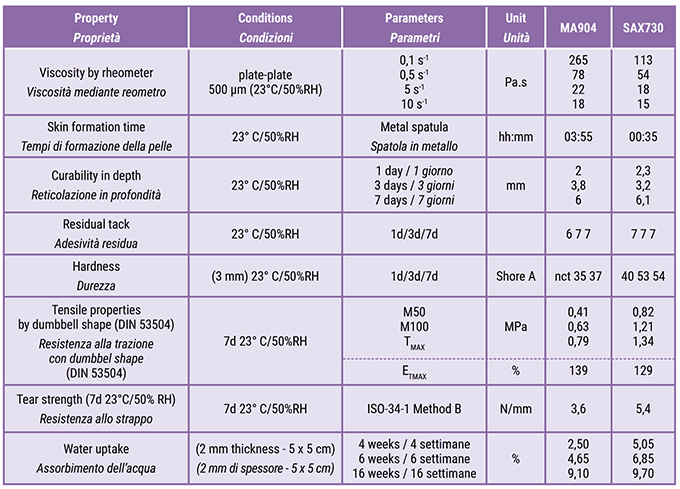

For liquid-applied membranes (LAM), good workability and low viscosity are essential for application via brush, squeegee, or foam roller. A high crosslink density ensures watertightness. Recommended Kaneka SilylTM grades include SAX535, SAX055, SAX350 and MA904. Typical technical values for a liquid-applied membrane are provided in Table 1.

EPDM AND TPO AHESIVES

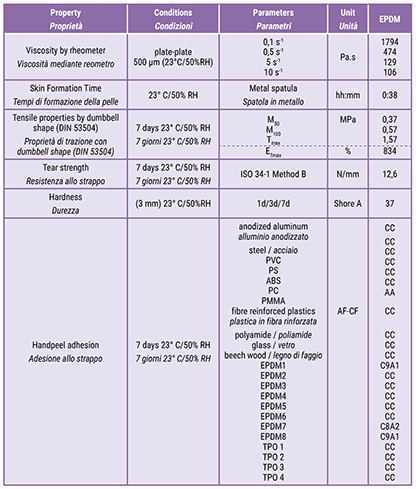

EPDM and TPO membranes are becoming popular waterproofing materials but pose adhesion challenges due to their composition. Traditionally, solvent-based adhesives have been used to overcome poor adhesion. However, Kaneka MS PolymerTM-based adhesives offer superior adhesion durability without solvents.

Advantages include an excellent adhesion durability compared to solvent-based adhesives and adhesive needs only to be applied on 1 side or 1 substrate eliminating open time and reducing overall work time.

The properties of an EPDM and TPO adhesive based on Kaneka SilylTM SAX220, when combined with specific raw materials, allow adhesion to most commercially available EPDM membranes. Table 2 provides further details.

LIQUID DETAILING AND FLASHING

These materials are used for sealing cracks, gutters, pipes, and replacing lead around chimneys. The polymer-based detailing and flashing products offer an excellent workability and adhesion. Compared to water-based acrylics, Kaneka MS PolymerTM-based LAM formulations cure faster at lower temperatures. Moreover, lower VOC emissions will be generated than with polyurethanes and they can be applied on wet surfaces. The technical characteristics of a liquid detailing product are very similar to the characteristics of a liquid applied membrane as shown in Table 1.

INDOOR WATERPROOFING

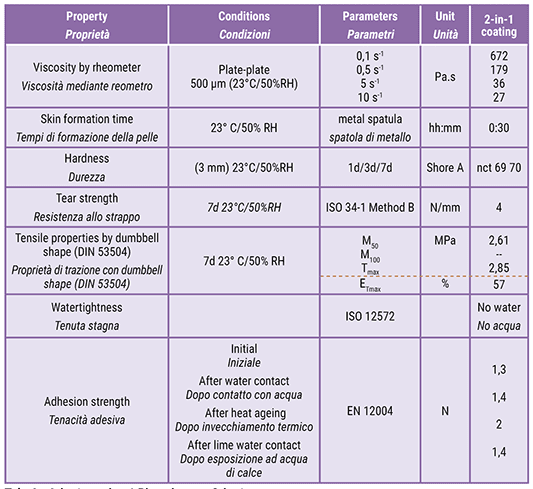

The same liquid-applied membrane used for roofing can also be used for waterproofing indoor walls and floors in wet areas such as showers and kitchens. For added functionality, the LAM was reformulated to also act as a tile adhesive, creating a 2-in-1 system that combines waterproofing with adhesion. Using Kaneka SilylTM SAX535 and SAX055, a low-viscosity coating was developed that maintains enough green strength to prevent tile sagging.

The 2-in-1 coating was evaluated according to various standards, as shown in Table 3.

CONCLUSION

The versatility of Kaneka MS PolymerTM makes it an ideal base material for waterproofing applications. This study demonstrates how its low viscosity enables easy application while ensuring watertightness and excellent adhesion to materials such as concrete, polyolefins, and plastics. A range of product grades is available, differentiated by backbone structure, functionality, and viscosity. This flexibility allows formulators to design sealants, adhesives, and coatings that meet required technical performance standards.