new silane-terminated polymers for sealants and adhesives

Florian Degenhart

WACKER

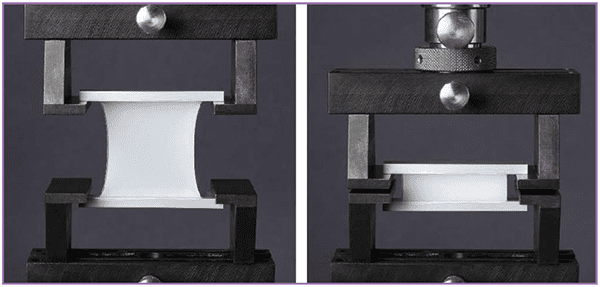

Laboratory tests show that sealants based on the Geniosil® STP-E 340 binder exhibit very good elastic recovery properties. Wacker premiered the product at the European Coatings Show in March

Wacker showcased a new generation of silane-terminated polyethers at the last European Coatings Show: Geniosil® STP-E 140 and STP-E 340. These novel polymers can be formulated into tin-free sealants and adhesives that are highly elastic and achieve a low modulus of elasticity – properties that are most desirable in the construction sector and a first in the adhesives and sealants world.

Tin-free assembly adhesives are yet another area of application that can benefit from these products. With these polymers, property profiles are now possible that comparable binders fail to provide. These silane-crosslinking binders are based on the company’s state-of-the-art Alpha3 technology. The polymers in question consist of both alpha and gammasilyl groups.

The alpha-silyl groups lead to greater reactivity, while the slower-reacting gamma ends have a positive impact on elastic recovery. This innovative technology thus combines the advantages of both alpha and gamma-silane-crosslinking polyethers.

Just like a conventional alpha-silaneterminated polymer, the combination of the two silane-terminated polyethers does not require a tin catalyst for curing. During crosslinking, the highly reactive alpha end literally pulls in the gamma end into the swifter curing process, which generally displays slower reactivity.

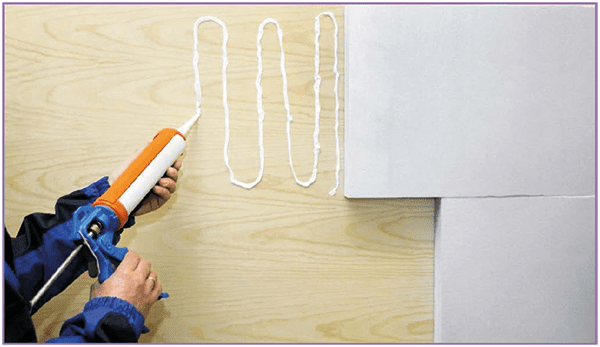

assembly adhesives

After crosslinking, Geniosil® STP-E 140 and STP-E 340 are highly elastic.

Application tests show that the silaneterminated polyethers adhere to a wide range of varying substrates. Both binders can be processed into creep-resistant, fastcuring adhesives. They also facilitate the production of low-modulus sealants. These are flexible and even without the application of much force, retain elasticity. Moreover, they also exhibit good elastic recovery, i.e. they return to their original length after exposure to prolonged elongation – a combination of properties that is unusual for conventional alpha-silanes.

The two binders differ in terms of viscosity. At 10,000 millipascal seconds, Geniosil® STP-E 140 is more fluidlike than STP-E 340, which has a viscosity of 30,000 millipascal seconds.

This makes it easier to tailor the finished product to meet the requirements of the relevant application. Adhesive and sealant formulators can process these polymers in a similar fashion as conventional silane-terminated polyethers. Even formulations without solvents and plasticizers are possible.

Incompatibilities with ester-based additives are eliminated, as the polymers crosslink without a tin catalyst. This increases the scope for novel formulation developments

and improves the storage stability of the formulated

finished product.

Both binders can be blended with all Geniosil® silaneterminated polyethers. It is thus possible to tailor the crosslinking rate, skin-over time, and the mechanical and elastic properties of the finished products to precisely meet the requirements of the end user. The new silaneterminated polyethers therefore can now address a diverse range of tin-free formulated adhesives and sealants.

Adhesives and sealants based on these polymers can be processed and applied without any need to change existing mixing or processing methods. Particularly the craftsman will benefit from the characteristic ease in handling such hybrid products.