The new frontier of non-structural two-component adhesives for wood compliant with the new EN 17619 regulation

Fabio Chiozza

VINAVIL

INTRODUCTION

A new standard (EN 17619), that classifies non-structural wood adhesives for external use, has recently been issued. This new classification fills the gap between structural and nonstructural applications and defines adhesives that can be used for non-structural wood applications without surface treatment.

Examples of outdoor application include swimming pool boards, playgrounds and outdoor furniture, log cabins, etc. The Italian chemical company VINAVIL SPA has developed a new range of two-component adhesives in compliance with the recently issued EN 17619. These adhesives are a blend of existing Vinavil chemical compounds and can be purchased as individual components (separately) and blended to the desired quality according to the Technical Data Sheet. Vinavil 2K glue classified as XT5 is an easy to handle two-component adhesive system (Vinavil XT 500 polymer dispersion and Vinadur 500 hardener).

It has a very long pot life (>5 days) to allow the assembly of large wooden structures in severe environments. The 2K glue classified as XT6 is a twocomponent system (Vinavil XT 700 polymer dispersion and Vinadur 700 hardener). It is a very reactive system (with a maximum 5 minutes open time) and allows the assembly of wooden joints in even more extreme environments.

STANDARD EN 17619

Until now, different types of adhesives have been used for non-structural outdoor wood applications, but without any real guidelines. This has led to the use of a wide range of polymer-based adhesives (from thermoplastics to thermosets – PU, PRF, PVAc, etc.) with even excessive performance and unnecessarily high prices. The new EN 17619 fills the regulatory gap between the classification of structural and non-structural adhesives. It defines adhesives that can be used for non-structural wood applications for outside uses without surface coating protection. Examples of application include swimming pool boards, playgrounds and outdoor furniture, log cabins, and other wooden structures where the adhesive reinforces the mechanical structure of the wood.

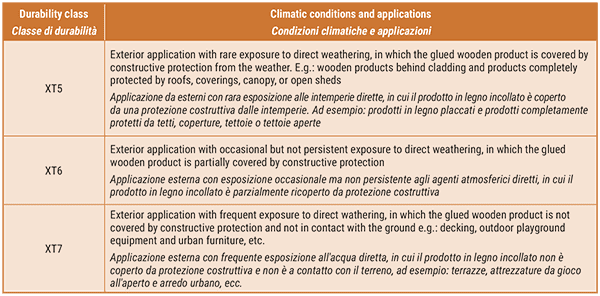

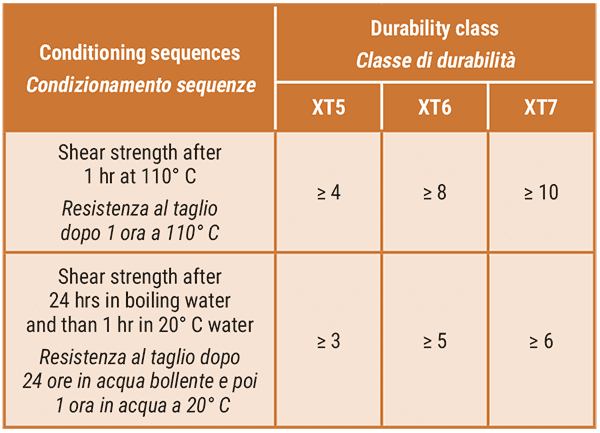

The new standard provides three durability classes, as seen in the Table 1. The adhesives belonging to XT classes should have a minimum durability class of D4, as specified in EN 204. Then, the performance of the adhesives shall be carried out with a tensile shear test after two different conditioning sequences:

• 24 hours boiling water immersion, followed by 1 hour cooling in water at 20° C.

• Heat conditioning for 1 hour in a ventilated oven at 110° C.

The high-performance levels achieved after boiling water and heat exposure can be used to select the proper adhesive for the specific exterior use.

NEW EN 17619 COMPLIANCES

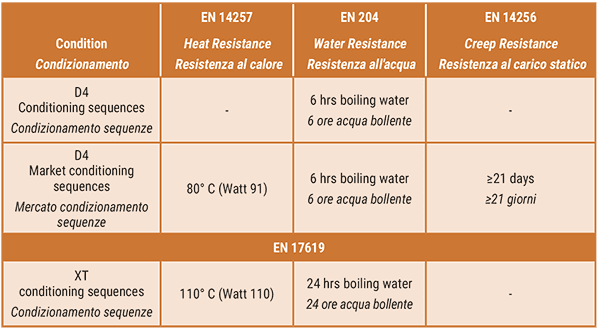

Achieving high performance by both boiling water and high heat exposure sorts Vinavil adhesives suitable for the specific exterior category. The XT durability conditions stipulated in EN 17619 exceed the durability conditions required in EN 204 (D4 classes), as shown in the Table 2. To meet the durability class requirements in EN 17619, the adhesive must have the shear strength values indicated in Table 3.

FROM THERMOPLASTIC POLYMERS TOWARDS THERMOSETTING ADHESIVES

Thermosetting resins constitute the main type of adhesives presently used to bond wood in structural, exterior applications, because of their high degree of durability. Durability requires that the adhesive not only has good initial bond strength but also maintains it on exposure to environmental service conditions (high humidity, freeze-thaw cycles, and temperature variations).

PVAc based polymers are thermoplastic and are commonly used for non-structural applications.

WATT91 (EN 14257), D4 (EN 204) and creep resistance (EN 14256)

Nevertheless, there are specific applications that are between structural and non-structural applications. The new challenge for the company is to fill that gap by giving the opportunity to the thermoplastic nature of the basic polymers to acquire thermosetting properties in the final adhesives.

This 2K glue classified as XT6 (100 pbw of Vinavil XT 700 + 20 pbw of Vinadur 700) is the result of the company’s R&D activity: starting from a thermoplastic polymer emulsion, the suggested formulation behaves as thermosetting adhesive that crosslinks very quickly to provide optimum properties.

The main advantage of thermosetting wood adhesives specified by the new EN 17619 is their high degree of resistance to exterior environments including heat and boiling water.

A NOVEL RANGE OF ADHESIVE SOLUTIONS

Vinavil has developed a new range of two-component adhesives in compliance with the recently issued EN 17619 XT classification.

These adhesives are a blend of existing Vinavil chemical compounds and can be purchased as individual components that can be bought separately and blended to the desired quality. These adhesives meet the durability standards required by EN 17619.

Vinavil’s compliance with EN 17619 has been confirmed by CATAS Spa, an international center of excellence for testing in the wood and furniture industry. Further certifications can be obtained based on market need and demand. Consistent EN 17619 performance ensures well-bonded, non-structural, timber products for exterior applications.

These adhesive systems guarantee excellent outdoor performance and provide unique application characteristics.

COLLA 2K CLASSIFICATA COME XT5

Si tratta di un sistema adesivo bicomponente facile da gestire. Ha una durata di vita utile molto lunga fino a 5 giorni per consentire l’assemblaggio di grandi strutture in legno in ambienti difficili.

Dei semplici miscelatori rotanti possono essere utilizzati per mescolare la dispersione polimerica XT 500 con l’indurente Vinadur 500. I componenti della colla (Vinavil XT 500 e Vinadur 500) non richiedono etichettatura di pericolo, come indicato dall’HSE, sebbene, in base alla certificazione GHS-US. XT 500 è classificato H315 (irritante per la pelle) e H319 (irritante per gli occhi).

2K GLUE CLASSIFIED AS XT5

It is an easy to handle two-component adhesive system. It has a very long pot life up to 5 days to allow the assembly of large wooden structures in severe environment. Simple rotating mixers can be used to mix XT 500 polymer dispersion with Vinadur 500 hardener. The components in the 2K glue class XT5 (Vinavil XT 500 and Viandur 500) do not require hazardous labeling, as indicated by the HSE, although, under GHS-US certification. XT 500 is classified H315 (skin irritant) and H319 (eye irritant).

2K GLUE CLASSIFIED AS XT6

It is a two-component system (Vinavil XT 700 polymer dispersion with Vinadur 700 hardener). It is a very reactive system with a maximum 5 minutes open time. Even if the components easily mix together, mixing is suggested using a dynamic in-line mixer due to the high reactivity. Vinavil XT 700 polymer dispersion does not require hazardous labeling, as indicated by HSE. However, Vinadur 700 is classified as harmful if inhaled and as a ‘probable health hazard’ (cancer and organ damage). The handling of the hardener requires the knowledge of preventive safety measures described in safety data sheet. All the diisocyanate users must have successfully completed a specifically training course from the 24th of August 2023.

SUMMARY

• The new EN 17619 standard makes it possible to select the correct adhesive for exterior wood applications that cannot be defined as either ‘structural’ or ‘non-structural’.

• Vinavil has introduced the new Vinavil XT range which allows it to offer the market adhesives classified XT5 and XT6, certified by CATAS Spa, an international centre of excellence for testing in the wood and furniture industry.

• The end-user, thanks to the new EN17619 standard and the new range offered by Vinavil, is facilitated in the choice of the most suitable adhesive for specific applications such as street furniture, wooden equipment for outdoor playgrounds, cladding and decking.