A PFAS-free future for adhesives

Stefania Musolino – XLYNX MATERIALS

As industries worldwide pivot toward sustainable solutions, XLYNX Materials, a Canadian innovator in polymer adhesion, is spearheading the move to a PFAS-free future with cutting-edge technology that delivers superior performance without environmental compromise. Per- and polyfluoroalkyl substances (PFAS), often referred to as ‘forever chemicals’, have long been a staple in adhesives due to their unique properties. However, growing regulatory scrutiny and environmental concerns have driven a demand for alternatives. The company has risen to the challenge by eliminating PFAS from its adhesive and primer formulations, setting a new standard for sustainable materials.

Redefining adhesion without PFAS

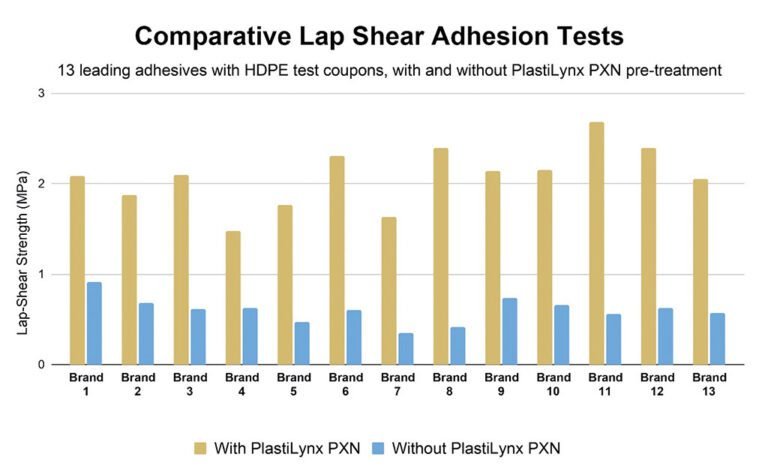

At the forefront of XLYNX’s innovation is PlastiLynx PXN, a PFAS-free primer specifically designed for polypropylene (PP) and polyethylene (PE). Unlike conventional primers, which are often limited to cyanoacrylate adhesives, PlastiLynx PXN delivers:

– broad compatibility: Works seamlessly with 15 leading adhesives, including epoxy, polyurethanes, and cyanoacrylates.

– Enhanced performance: Demonstrated 150%-350% stronger adhesion on PP/PE substrates in head-to-head comparisons with established polyolefin primers.

– Sustainable design: Eliminates PFAS and utilizes rapid curing with UV light or moderate heat, offering a longlasting solution without damaging substrates.

“This primer truly sets a new benchmark”, remarked Dr. Stefania Musolino, Head of R&D at XLYNX Materials. “With PlastiLynx PXN, we’ve created a sustainable solution that not only meets environmental demands but also surpasses conventional primers in versatility and performance. It’s a game-changer for manufacturers across industries”.

Extending innovation with BondLynx BXW-202

Complementing PlastiLynx PXN is BondLynx BXW-202, a fluorine-free molecular adhesive built on bis-diazirine crosslinking technology. Engineered to bond low-surface-energy plastics like PP and PE, BondLynx has expanded its applications to include microelectronics, textiles, and surface functionalization.

In comparative tests, BondLynx BXW-202 outperformed competitors across the board, offering:

– 124% stronger adhesion for PP.

– Over 300% stronger adhesion for PVC rubber.

– More than 200% stronger adhesion for HDPE.

A sustainable path forward

As global industries seek alternatives to PFAS, the Canadian company is leading the charge with innovative solutions that align with environmental priorities and deliver exceptional results. “Our goal is to innovate responsibly, creating materials that perform better while reducing environmental impact”, Dr. Musolino added. By setting a benchmark for sustainable adhesion technology, the company is helping manufacturers transition to a cleaner, more efficient future.