How structural adhesives are revolutionising solar PV installation

Andrew Harvey – SCOTT BADER

Scott Bader is a world leading global chemical company employing 800 people across 8 manufacturing sites and 19 commercial offices around the world. Using its global resources and combined expertise, the company continues to be a leading manufacturer of products for the composites, advanced composites, adhesives and specialty polymers markets, offering a full range of technologies and manufacturing capabilities for many market sectors.

In this article, the company’s solar PV expert, Andrew Harvey, talks about the improvement of the structural adhesives for solar installation, and how they should be used for optimum installation.

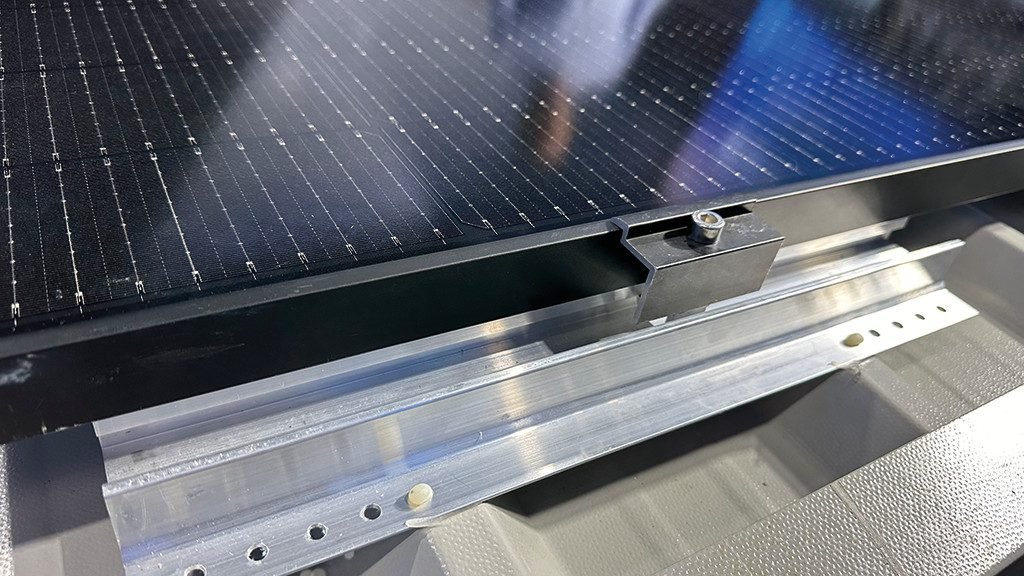

The flexible solar PV panels can be bonded directly to roofs. Traditional glass faced solar panels can be installed by bonding the aluminium rails, that hold the solar panels, to the roof.

Bonding flexible solar PV panels or aluminium rails, for the installation of traditional glass faced to solar PV, avoids drilling holes in the roof and the risk of rainwater leaks. It also avoids invalidating the warranty supplied by the roofing manufacturer on the water tightness of the roof. In coastal areas there can also be issues with galvanic corrosion where the roof and mechanical fastener starts to rust which will affect the long-term durability of the installation.

What is the product offering from Scott Bader in the solar PV market?

Our Crestabond M7 range are methyl methacrylate adhesives designed for bonding flexible solar PV panels and aluminium rails for the installation of traditional solar PV to rooftops. It is also primerless, meaning the installation is fast and simple.

What types of roof can you bond to?

The adhesive can be used to bond aluminium rails to all types of metal roofs, including standing seam, trapezoidal metal roof panels, polyester spray or powder coated and PVC plastisol coated roofs. For flexible solar PV panels, which are typically 80% lighter compared to traditional glass faced solar PV, the adhesive can be used to bond the panels directly to metal or metal coated roofs and PVC single ply membranes which are used extensively on flat roofs of commercial buildings & residential apartments.

What about the strength of the attachment ad how does it compare to mechanical festeners?

On thin gauge steel trapezoidal roofing, 0.5 mm, the bond strength when using Crestabond M7, is up to three times higher compared to a mechanical fastener.

This is because, when using a battery powered screwdriver and Tek screws, the thread created in the steel is limited and can be easily threaded if the screwdriver torque is too high. For thicker gauge steel roofs of 0.7 mm the strength of a bonded rail and mechanically fastened rail, when installed according to manufacturer’s recommendations, will be similar and will accommodate the load imposed by over 3 times the wind speeds typically imposed by a typhoon.

What warranty can be offered that the adhesive sill last the 25-year service life of the solar PV panels?

Testing, static and after climate cycling, has been conducted to confirm that the adhesively bonded rail or flexible solar panel will last the 25-year service life of the solar PV panel. However, there are variables which cannot be controlled by Scott Bader such as roof preparation and correct storage/usage of the adhesive cartridges which can affect the strength of the bond. Simple tests can be conducted on site by the main installation contractor to check the quality of the roof coating and if needed, for large commercial installations, testing can be conducted by Scott Bader and a report issued to verify the bond strength/durability based on a sample of the roof panel and rail provided; this will provide confidence that the bonded flexible solar PV panels or aluminium rails will meet the requirements for the project.

What is the process and how long does it take to bond flexible solar panels or aluminium rails to roofs?

Scott Bader’s detailed step by step installation guides, available below, cover every aspect of the installation from the roof preparation to the installation of the flexible solar PV panels or aluminium rails; the process is very simple and in reality, will be quicker than using mechanical fasteners. The roof should be cleaned with soapy water or if heavily soiled using a jet wash and then allowed to dry before bonding the flexible solar PV panels or aluminium rails.

Can the flexible solar panels or the aluminium rails be removed if needed to replace a damaged panel or for routine maintenance of the roof?

For flexible solar panels there are two options. Firstly, if the panel is damaged and bonded to the roof then the junction box at the top of the panel can be removed and a new panel bonded directly on top of the existing panel. Secondly, if bigheads or bonding plates have been used to attach the flexible solar panel to the roof, the panel can be easily removed by unscrewing the attachments.

For aluminium rails, a paint stripping gun (battery or mains powered) can be used to heat the rail to a temperature of approximately 150° C at which point the roof coating or adhesive will soften allowing the rail to be removed. A local repair of the roof coating can be made with a colour match paint.

How easy is it to use and apply the company’s structural adhesives?

The adhesive is supplied in a cartridge format together with a mix head and can be dispensed using a manual, pneumatic or battery powered dispense gun. When using Crestabond M7-05 at an ambient temperature of 23° C the working time is approximately 5 minutes. Within 15 to 20 minutes it will have developed sufficient strength to start installing the traditional solar PV panels.

This time will vary depending on ambient temperature and reference should be made to the relevant technical data sheet.

Does the weather impact on when flexible solar panels and aluminium rails can be installed with the adhesive?

The flexible solar PV panels and aluminium rails can be bonded at any ambient temperature from 0° C to 30° C but the installation should not be conducted in the rain or where there is excessive moisture on the surface of the roof. The roof should be relatively clean and dry.