Enhancing manufacturing efficiency with fast-cure structural adhesives

David Tobler

SIKA

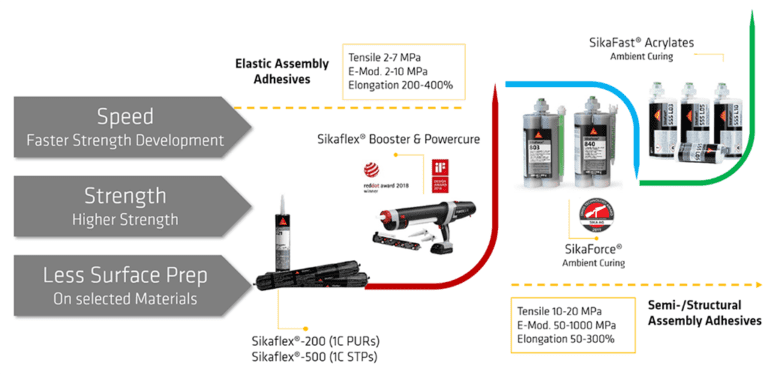

In today’s competitive manufacturing landscape, efficiency and sustainability play a crucial role. The use of fast-cure structural adhesives has become a game-changer, ensuring optimal manufacturing processes across various industries. These adhesives develop strength quickly, enabling manufacturers to reduce takt time significantly. However, the industry faces challenges with the availability of traditional twocomponent (2C) adhesives, particularly due to packaging constraints. Traditionally, 2C adhesives are dispensed from plastic cartridges, generating significant packaging waste. This method not only impacts environmental sustainability but also faces supply chain issues. As of 2022, the availability of such packaging has been very limited in the European market, making many adhesives unavailable to manufacturers. This unavailability risks halting production lines, directly affecting revenue and supply capabilities.

Benefits of two-component adhesives

2C adhesives are particularly valuable in applications requiring high-strength bonds, rapid handling strength, or extensive joints where curing times can be prolonged. These adhesives are essential in various industrial processes due to their robust performance characteristics.

In smaller, hand-applied applications, two-component adhesives are typically dispensed from plastic cartridges.

However, this method generates substantial packaging waste and has the disadvantage of low extrusion rates due to the static mixers that are used in the process. Despite these drawbacks, the superior bonding capabilities and faster curing times of two-component adhesives make them a preferred choice in many manufacturing scenarios.

Enhanced adhesive technology for improved efficiency

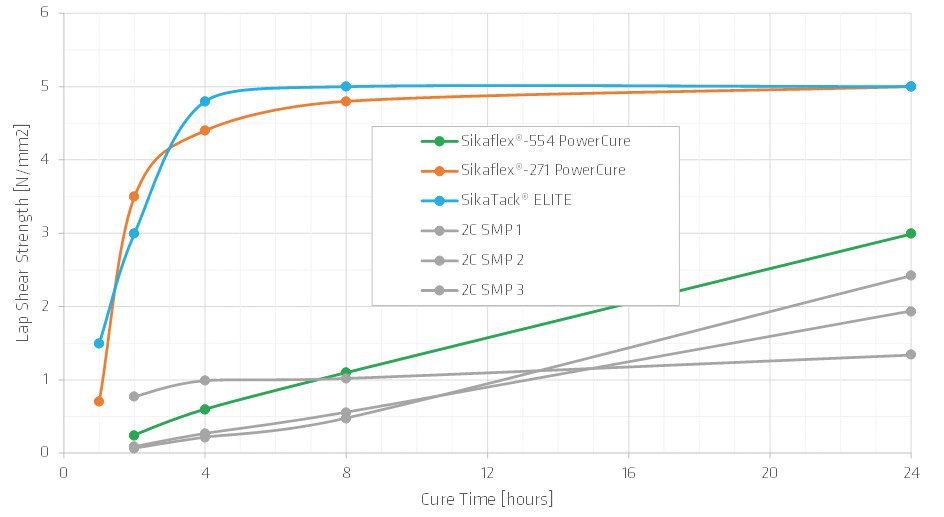

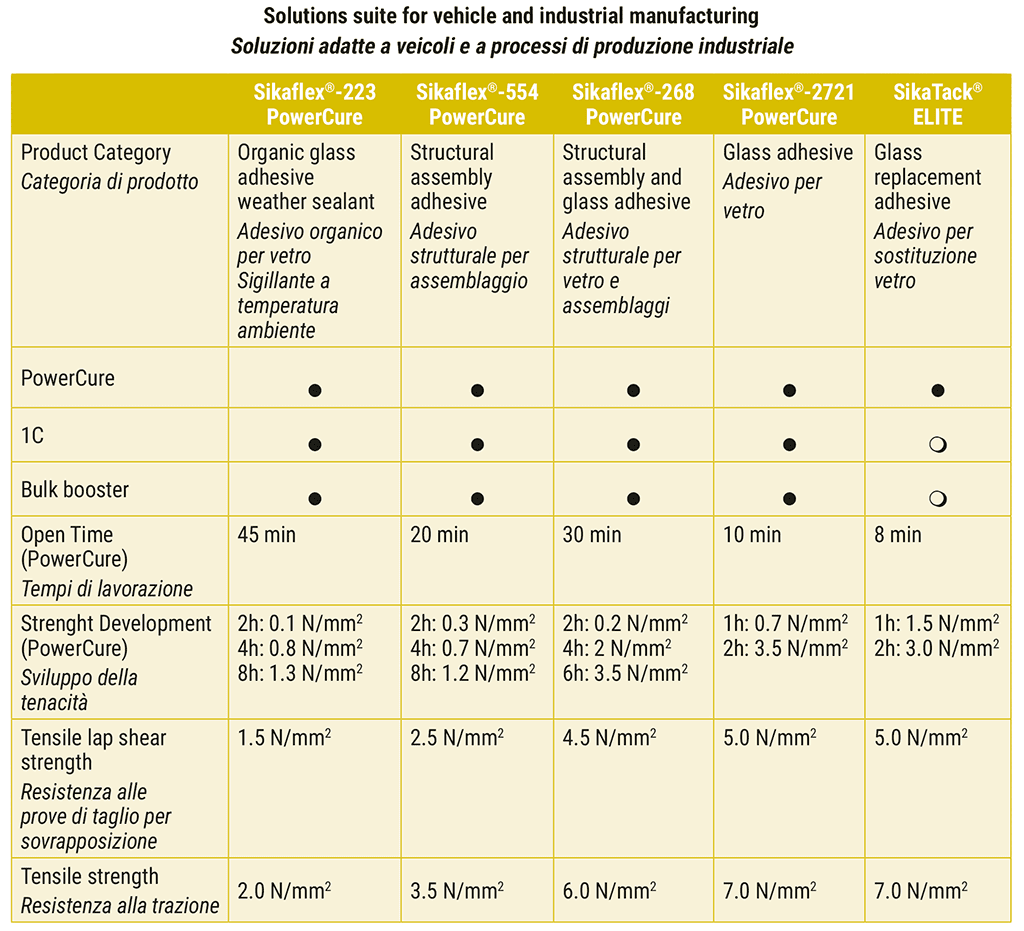

Sika’s fast-curing Sikaflex® PowerCure adhesives provide a reliable alternative to traditional 2C systems. These innovative adhesives, unaffected by current market limitations, ensure continuous availability and offer several advantages over conventional 2C systems.

Two-component adhesives are preferred for their strength and quick handling times, making them ideal for applications requiring extensive joints or faster curing times. However, the traditional packaging of 2C adhesives in plastic cartridges leads to substantial waste and inefficiencies.

The Sikaflex® PowerCure System represents a significant advancement in adhesive technology, offering accelerated curing for one-component materials. By incorporating a 2% waterbased accelerator paste, these adhesives achieve rapid and thorough curing without altering the final material properties. This innovation allows engineers to efficiently scale adhesive bonding processes without the need to redesign joints.

What applications can be supported with the Sikaflex® PowerCure system?

These adhesives, enhanced with a 2% water-based accelerator paste, cure faster than many traditional 2C systems. These adhesives are suitable for:

• assembly of large parts requiring specific work times (e.g., 2C SMPs in cartridges).

• Bracket and holder assemblies where speed is crucial (e.g., fast cure MMAs, Acrylates).

• Bonding different materials with joint thicknesses of 4 mm or more (e.g., PURs, SMPs, MMAs).

However, there are certain applications where the Sikaflex® PowerCure may not be suitable. Thin layer bonding: this adhesive is generally not recommended for adhesive applications involving thin layers with a joint design of less than 1 mm.

High-Temperature processes: these adhesives are unsuitable for applications that undergo powder coating or other processes with baking temperatures exceeding 120° C. High-Strength Requirements: these adhesive products are typically limited to a tensile lap shear strength of around 5 N/mmÇ. In many cases, they may still be suitable after a thorough assessment of the specific use case, though a redesign of the joint may be necessary.

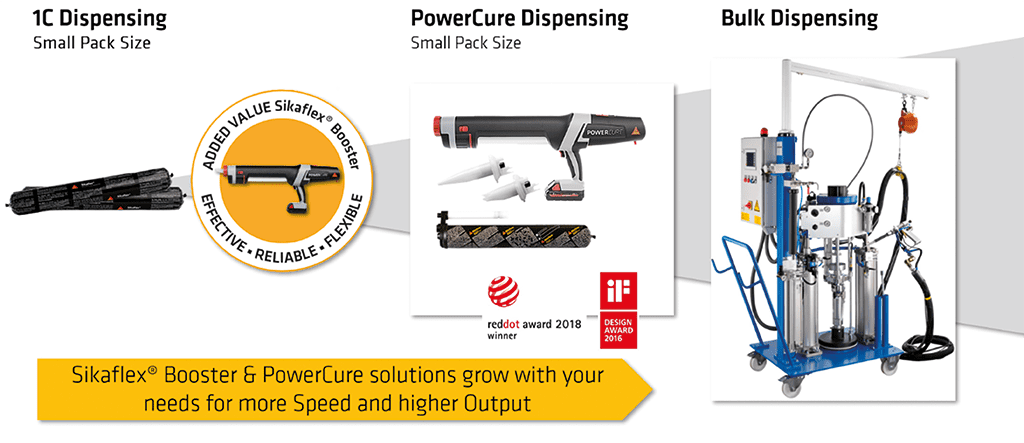

Flexible packaging and dispensing options

PowerCure not only refers to the high-performance adhesive but also to its innovative packaging and dispensing system, designed for small pack sizes. For bulk dispensing, the Sikaflex® Booster is employed, providing the same high-quality materials in larger quantities.

Advantages of the adhesive

Sikaflex® PowerCure adhesives outperform traditional cartridge materials in several key areas:

– reduced Packaging Waste: Up to 60% less packaging waste, contributing to environmental sustainability.

– Reliable Product Availability: Ensures a consistent supply of adhesives for uninterrupted operations.

– Increased Extrusion Rate: Faster extrusion rates compared to common two-component materials, enhancing productivity.

– Versatile Fast-Cure Options: Offers a wide range of fastcuring products to meet diverse application needs.

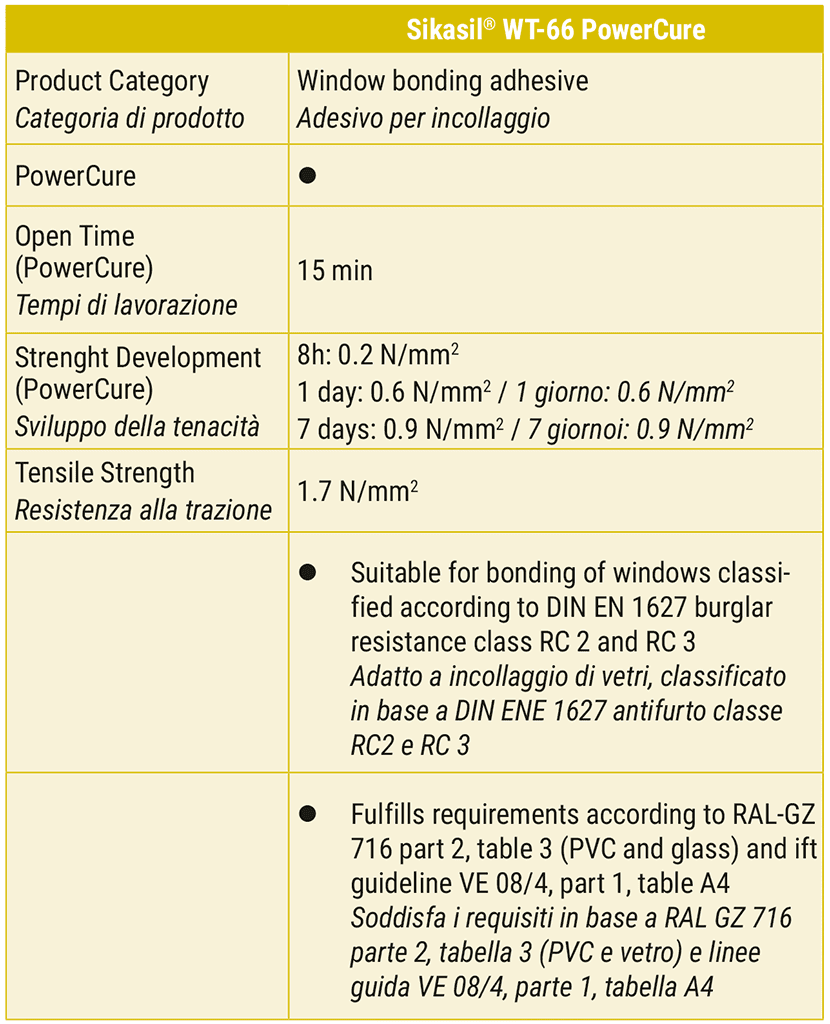

Solutions suite for manufacturers of residential glass

Sika PowerCure adhesives that are specially designed for structural glass bonding application are ideal for on-site application of burglar-proof windows. Boosted silicones combine the benefits of both one- and two-component adhesives: Climate-independent and quick-curing along with easy manual application. There is nearly no limit to how the products can be used, including working in harsh outdoor conditions that are typical for window repair.